There are thousands of different blends of plastic in the world. The key to plastic repair is knowing which plastic you're working with and choosing the appropriate repair material to match. Watch the video to learn our tips and master the plastic repair process.

Even the most rugged vehicles eventually begin showing the effects of UV exposure. Refinishing faded trim can instantly enhance the look of a vehicle for significantly less cost than replacing the panels. The process is simple and SEM offers a variety of trusted products for matching color and gloss of trim components.

SEM SOP: GripTide™ Non-Skid Deck Coating

Now is the perfect time to plan ahead for the next boating season! If you're looking for a durable, non-skid coating with a simple application process, GripTide Non-Skid Deck Coating is an ideal solution. Learn to apply GripTide in five simple steps.

SEM SOP: Filling Custom Fill™ Aerosol Blanks

Increase revenue with SEM's Custom Fill™ system designed for custom matching vinyl, leather, plastic, carpet, velour, or properly prepped and primed metal. Learn how to fill aerosol blanks with SEM's Standard Operating Procedure.

Replace or repair a scratched or scuffed mirror?

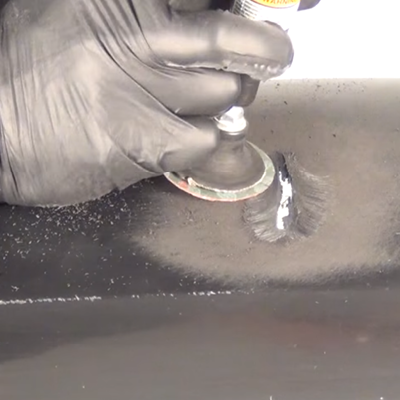

As manufacturers seek new ways to make lighter cars, plastic becomes more prevalent in the newer model vehicles. Replicating OEM textures in the shop eliminates the need to wait for replacement parts.

SEM’s Texture Coating duplicates OEM textures, increases your billable hours and returns cars to customers faster.

SEM - It's About More Than Just Products

SEM Products is committed to designing and delivering top performing products that reduce time, steps and waste for collision centers. In this quickly changing industry, innovation is essential to keeping up and staying in the game.

We also know it takes more than best-in-class, OEM recommended products to complete flawless repairs in record time. You need experience, skill and know-how. That's why we prioritize...

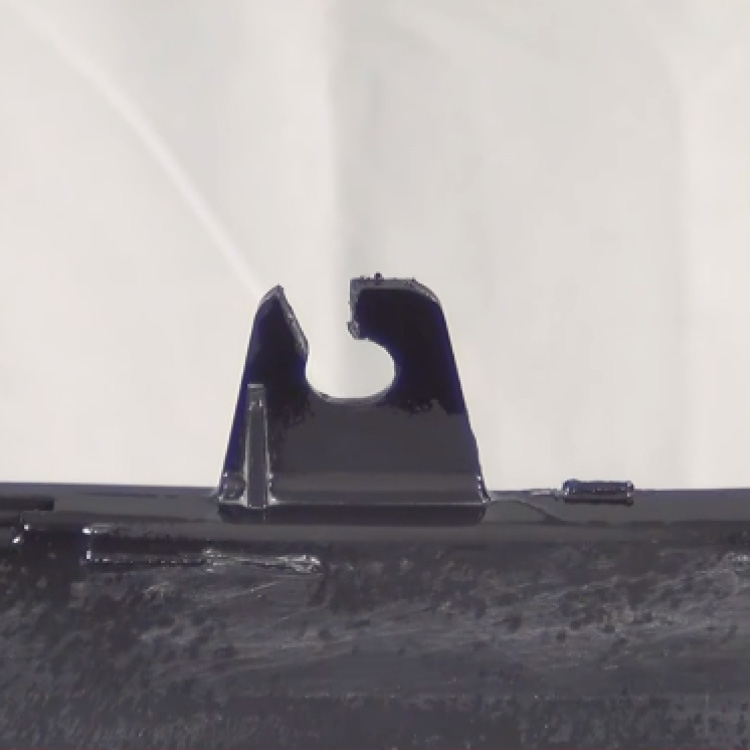

Panel & Rivet Bonding Standard Operating Procedure (SOP)

Use SEM's five step standard operating procedure (SOP) for flawless panel and rivet bonding repairs.

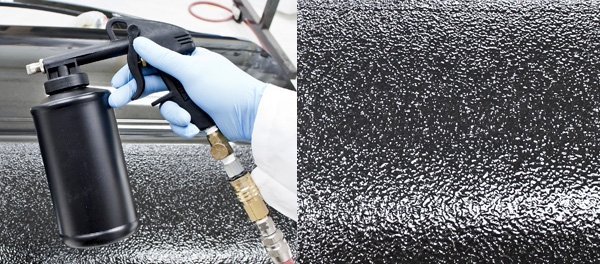

Truckbed Liner Standard Operating Procedure (SOP)

Follow SEM's three step standard operating procedure (SOP) for professional truckbed liner application.