Watch & Learn: Plastic Repair

Fun Fact: Plastic repair came onto the collision repair scene as a result of the first oil embargo of the early 1970s. The first C.A.F.E. standards passed by the government initiated OEM's to innovative lighter-weight vehicles. Their solution: replace steel with plastic, where possible. Plastic bumpers were lighter, more impact resistant, and could be easily molded for better aerodynmaics.

So, how does this history tidbit affect collision repair technicians today? There are thousands of different blends of plastic in the world. The key to plastic repair is knowing which plastic you're working with and choosing the appropriate repair material to match.

Watch the video or read the recap below to learn more.

Two Main Types of Automotive Plastics

In the automotive market, there are two main types of plastic.

- Thermoset plastics - This category represents the highly flexible, yellow or tan plastics found on old Ford®* Crown Victoria's, Mustangs, dually rear fenders and some late-model Chargers. These plastics are usually easier to repair. Thermoset plastics DO NOT melt.

- Thermoplastics - This category accounts for up to 90 - 95% of the plastic bumpers technicians encounter today. It consists of the gray or black plastics which are semi-rigid as compared to thermoset plastics. These plastics DO melt, which also means they are recyclable.

How to Identify the Type of Plastic

Traditionally, technicians identified plastic by searching the back of the bumper cover for an ID number and referencing that number in a catalog. Thankfully, those days are over because we have a few simple methods of identifying which type of plastic you're working on.

- Look at the color. Remember thermoset plastics are typically yellow or tan, while thermoplastics are usually black or gray.

- See if the plastic floats. Cut a sliver off the bumper and drop it into water. Thermoset plastics sink, but thermoplastics will float.

- See if the plastic melts or powders. Thermoset plastic will powder while thermoplastics melt.

Three Products for Plastic Repair

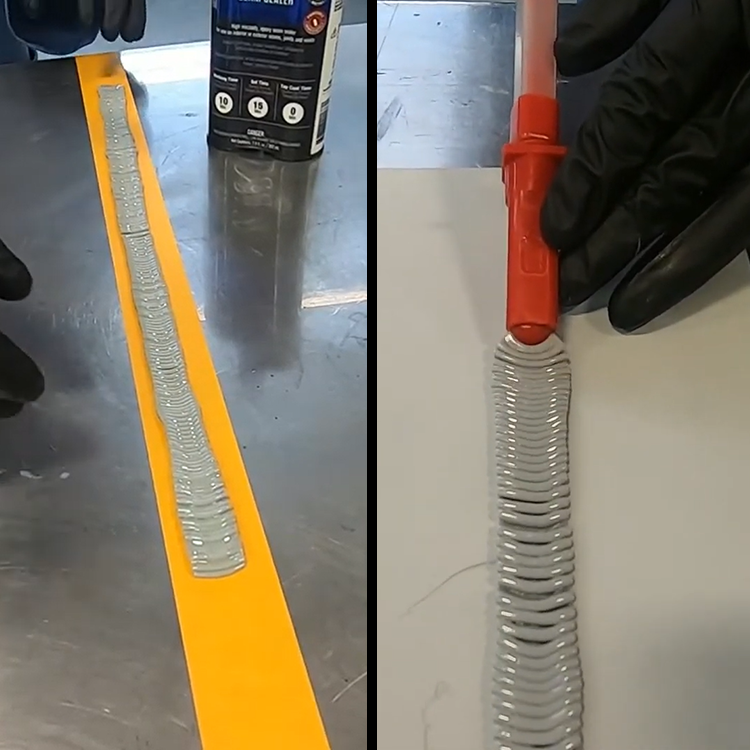

- Dual-Mix Problem Plastic Repair Material is designed to work with semi-rigid thermoplastics. Due to Problem Plastic Repair Material's semi-rigid nature, this product should not be used on yellow or tan plastic.

- Dual-Mix Multi-Plastic Repair Material works on both flexible and semi-rigid types of plastic.

- Dual-Mix Rigid Plastic Repair Material is designed for the commercial industry, ideal for repairs on 18-wheelers with rigid plastics such as Metton®*, SMC, or fiberglass repair.

Of all the changes in our industry, one of the biggest is around the OEM statements about sensors that exist behind the bumper covers. Always follow OEM guidelines, some may call for no repairs and replacement only.

*All trademarks shown are registered trademarks of their respective holders.

Recent Posts