SEM SOP: Filling Custom Fill™ Aerosol Blanks

Increase revenue with SEM's Custom Fill™ system designed for custom matching vinyl, leather, plastic, carpet, velour, or properly prepped and primed metal.

Custom Fill machines allow users to fill aerosol cans with a multitude of products including primers, clear coats, and single-stage paints with three aerosol blank options.

- 61993 | Custom Fill Aerosol Blank for filling with a variety of solvent-based automotive paints

- 62003 | Custom Fill Waterborne Aerosol Blank for filling with Sure-Coat™ mixed color and automotive waterborne basecoat

- 62013 | Custom Fill+ High Build Aerosol Blank for higher film build and quicker coverage with 1K and 2K* solvent-based primers, color and clear

*Pot life of cans filled with 2K product typically range from 1 - 7 days. Due to the variety of products available, exact pot life will need to be determined by the user.

The easy-to-use Custom Fill machines and aerosol blanks allow for limitless color combinations for solvent and waterborne paint systems to increase revenue and throughput. Below are five simple steps for filling aerosol blanks.

STEP 1: PREP

Remove disc from cap and insert over piston inside the fill machine. Place clear, plastic cap into the Fill Cylinder. Press down and rotate cap until it drops into place.

Note: Do not fill cap prior to inserting into Fill Cylinder and onto Custom Fill Aerosol Blank.

STEP 2: FILL THE CUP

Remove tip from the aerosol. Press cylinder cap assembly on top of aerosol blank. Fill clear plastic cap with paint to fill line located on inside of cylinder.

Note: Solvent blanks can be filled with urethanes, enamels, lacquers as well as 2K primers, sealers and clearcoats. The Custom Fill Waterborne Aerosol Blank can be filled with most waterborne basecoats and top coats. Always check for compatibility prior to filling.

Waterborne primers are not compatible.

STEP 3: LOCK ASSEMBLY IN PLACE

Place assembly into machine. Hold cylinder and can assembly in place and raise pedestal on bottom until it touches the bottom of the can. Close door on Custom Fill Machine.

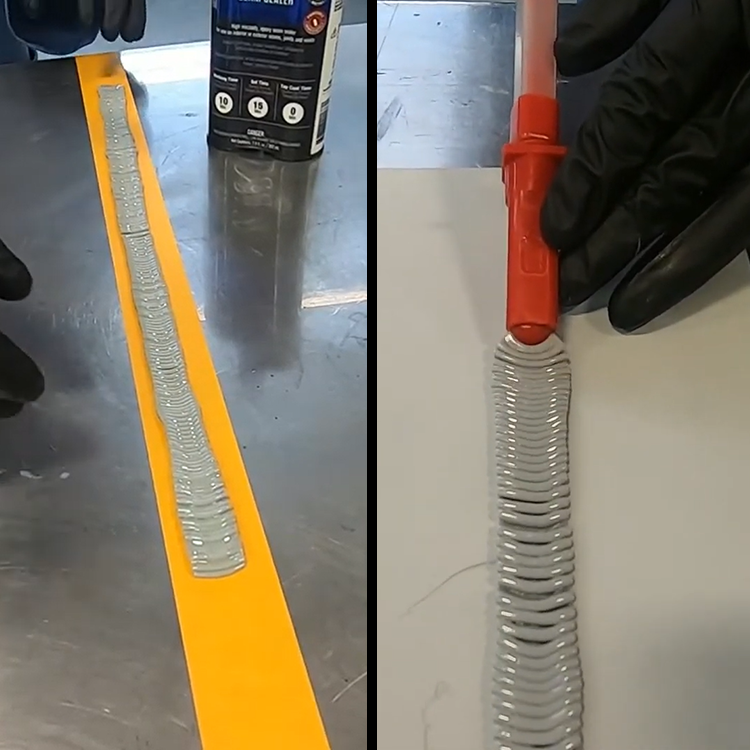

STEP 4: FILL THE AEROSOL

FOR MANUAL MACHINE: Rotate crank until it stops and then rotate in the opposite direction until it stops.

FOR PNEUMATIC MACHINE: After closing the door, the machine will fill the aerosol. Wait until the machine is silent.

Open the door and loosen pedestal to remove assembly from the machine.

STEP 5: REMOVE CAP AND REPLACE TIP

Remove cylinder/cap and can assembly from machine. Twist gently to remove cylinder from can. Hold cylinder and press down on a hard surface to remove cap. Replace tip.

Note: Purge valve by test spraying for a few seconds until spray is uniform. Clear nozzle/tip by inverting can and spraying until clear.

Mark filled aerosol with coating type, color name, date and MIR value.

>> Download the SOP

Recent Posts